Additional J160 conversion and modification information

The Toyota J160 / Aisin AZ6 gearboxes are lightweight but yet are still quite strong and shift very well. Covered here is some general information on their specifications and also conversion and upgrade information.

Additional information

NOTE: This is one of two articles that features information related to performing a J160 conversion, the other features a parts check-list and other additional information. It can be found here:

– A guide on performing a J160 gearbox conversion

In due time these two articles will be combined together for simplicity. It’s highly suggested to read both articles.

Available models and variations

The “J160” is the identification code as used by Toyota for their variants of the AZ6 6-speed gearboxes.

There were two main types of J160 pending on if they were used behind the 1GFE or the 3SGE Beams engines. The only difference between these two variants is the front / bellhousing part of the housing and possibly the speedo drive gear. Otherwise they are identical. Furthermore there were some small changes between an early and late type on both of these types.

Despite having the same “AZ6” model code from Aisin there is not that much in common between those as used on Toyota’s and other manufacturers. Here are all the vehicles that were potentially fitted with an AZ6 gearbox.

– Toyota Lexus – 1GFE engine

– Toyota Altezza – 3SGE engine

– Nissan S15

– Mazda MX5

– Mazda RX8

– NOT AN AZ6: Honda S2000 – It’s a common misconception that these are a variation of the Aisin AZ6 when they are not. These are a completely unrelated model of gearbox.

In terms of compatibility it remains to be seen which parts can be interchanged as even the housings vary between most of the makes, for example the front bellhousing section from a Toyota model will not bolt to the middle housing as sourced from a Nissan.

One modification that’s known to work well is to use the 6th gear-set sourced from the Nissan S15 AZ6 gearbox and fit into one of the Toyota gearboxes. The J160 uses originally uses a 0.869:1 ratio compared to the Nissan gear-set with it’s 0.767:1 ratio. This results in lower engine revs for the same vehicle speed during the use of the 6th gear.

Strength upgrade

The J160 / AZ6 gearboxes are reported to be able to handle a little less but close to the same torque as the earlier Supra / W5x models. However the limiting factor in the strength of any of the AZ6 gearboxes is apparently not the gears directly but rather a 2-part thrust washer.

The shaft for this thrust washer is only cut part of the way into the gear teeth and under high load they can chip the edge of the teeth and cause a complete failure. There is however a modification available from one company to cut this slot deeper and a new custom thrust washer supplied:

Nissan Silvia S15 6-Speed gearbox “Circlip Mod”. From the company “Neat Gearboxes”.

According to one source when used in a Nissan S15 the maximum torque ratings before a possible gearbox failure are as follows:

– Original: 220Nm

– Post modification: 500Nm

Although this modification is advertised as being for the Nissan gearboxes it is known to work exactly the same on Toyota’s J160’s gearboxes.

– NOTE: We do not offer this service nor the parts to undertake this modification.

Crossmember mount

To fit the J160 into a vehicle not designed for a new gearbox crossmember will need to be used. These are either custom made to suit or potentially purchased from custom parts suppliers. The original J160 rubber mount is original reused however something with a lower profile can instead be fitted if required.

For extra clearance a spacers can be added between the car body and the gearbox crossmember.

Speedometer / speedo cable

Original there is only a digital sensor / counter for the speed output of a J160. We offer a direct bolt in speedo drive to interface with the traditional speedo cable drive. Another option is to use this digital output directly into a digital dash module.

Gearstick position

Most J160 gearboxes have 2 different positions available. These can switched between by moving the main shifter housing to the other set of mounting bosses and reversing the cast iron rear piece on the shaft.

The issue is that even with the forward position used it’s still far too rearward for almost all conversions. We offer a bolt on conversion kit to move the shifter another 110mm forward which is near on where the gearstick would normally be held with a T50 gearbox in an AE86 / AE71. For more information and / or purchase please see here.

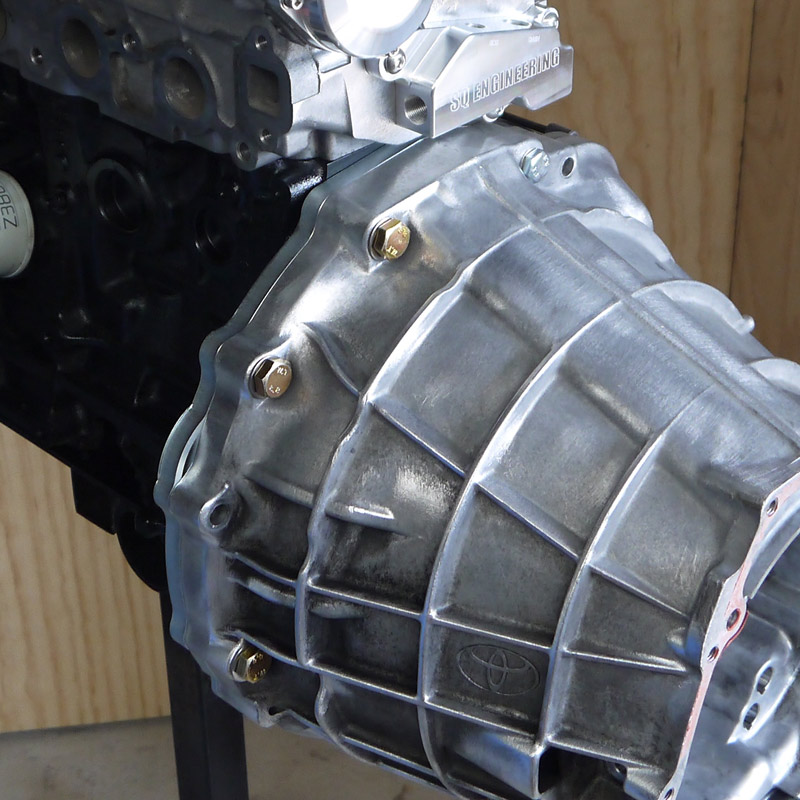

Firewall / transmission tunnel clearance

These gearboxes have a bulkier bellhousing profile than something like a T50 gearbox. This may well pose a clearance issue when fitting into a car such an AE86. Below are some of the options available when more clearance is required.

– Modification to the car body: The most direct solution but it may interfere with other systems such as the heater. It also requires the right equipment, skill and a large amount of time to do correctly. There are also potential legal and other issues.

– Modification to the Bellhousing shape: The car body is most likely to hit the top edge of the bellhousing about half way down the top bellhousing tapper. However there is a large amount of vacant space inside this housing at the top. So therefore providing enough room is left for the clutch and flywheel this area could be cut into for an extra space relief. To seal it back up a plate can welded over the exposed hole.

– Crossmember spacers: This is the easiest option of all but it does compromise the suspension geometry and the ground clearance. For the thinner spacers this isn’t much of an issue but otherwise avoid where possible.

Clutch compatibility and selection

The splined shaft that is used on the J160 gearboxes is identical to the common “Supra” style 5-speed / W55 to W59 models.

When adapting the gearbox to a different engine such as with our 4A to J160 adapter kit a different clutch combination is required from original.

– Flywheel: To suit the engine.

– Clutch pressure plate: To match the flywheel being used and as potentially fitted to the engine normally.

– Clutch friction disk: Needs to be compatible in terms of diameter and thickness with the pressure plate / flywheel being used but have a spline to suit the gearboxes input shaft. In some cases such as the 4agze clutch kits the friction disk that is supplied happens to have a correct spline. When this is so both the pressure plate and friction disk (not thrust bearing) from an off the shelf clutch kit can be used as is. For all other applications either the pressure plate and the friction disk are individually ordered or the disk customised to have the correct spline. There are compatible clutch disks available with various diameters such as 200, 212(215), 225mm and likely others. For example the most common diameter used on a 4age engine is 212mm, and a compatible disk in this size and the correct spline can be found sourced from one of the models of Hilux.

– Thrust bearing and carrier: The J160 originally use a combined thrust bearing and carrier unit. In a conversion a custom unit with a different bearing may be required to be made up. Alternatively a concentric slave cylinder may possibly be used to replace the thrust bearing and the clutch fork, clip and slave cylinder.

Tailshaft conversion

The output splines on a J160 are larger than that of a T50, these splines are the same as the W5x / Supra series as well as various other transmissions. As such there are tailshaft / Drive-shaft shops that stock new compatible yokes on their shelf that they can use to adapt to an existing tailshaft, change the length if necessary and then complete the modification with the whole tailshaft being balanced. Alternatively a compatible yoke from a different model can potentially be sourced second hand and adapted to the existing tailshaft in the same manner. A second option is to have a completely new two-piece custom up to suit but this would obviously be a much more expensive proposition.

WARNING ON USING SINGLE-PIECE TAILSHAFTS: It’s strongly suggested to NOT USE a single-piece tailshaft, as various people using them have reported having the rear housing of their J160’s crack or with at least one unfortunate individual the whole rear section of his gearbox broke completely apart, his photos were quite the sight to see. While unknown to us, this issue may possibly be avoided by using a very light carbon fibre tailshaft? Due to all of this it’s highly suggested to keep using a OEM style two-piece design.